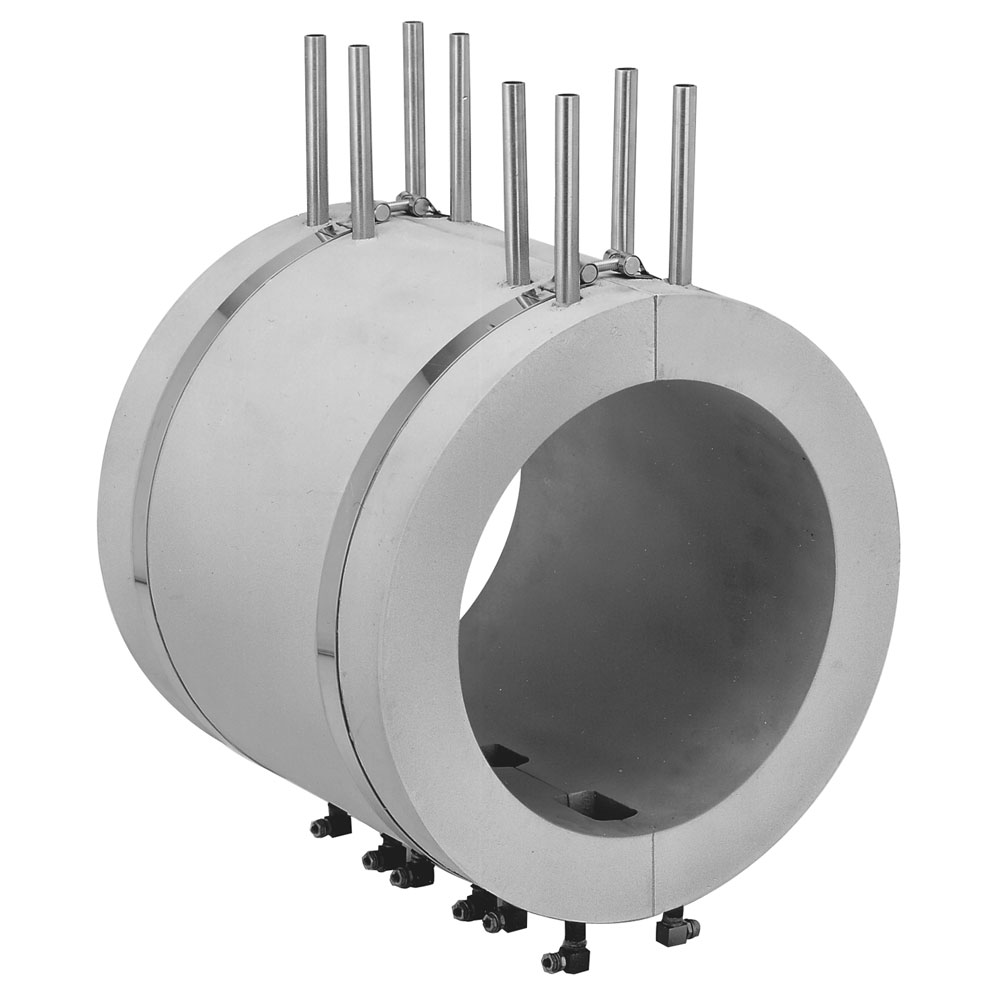

Cast-in Band Heaters

The primary application of Cast-in band heaters is to heat plastic extruder barrels. Though more expensive than available options like mica bands they will last significantly longer due to better thermal conductivity and available cooling options.

Max Temperature: 371°C (319 aluminum), 399°C (356 aluminum), 732°C (bronze), 649°C (yellow brass)

Max Voltage: 600V (depending on element diameter)

Max Wattage: 35W/in² (aluminum), 45W/in² (brass or bronze)

Max Amperage: 40A (depending on element diameter)

Weight: 0.101lbs/in³ (319 aluminum), 0.096lbs/in³ (356 aluminum), 0.272lbs/in³ (bronze), 0.304lbs/in³ (yellow brass)

Types: Air cooled (finned), Liquid cooled (cooling tubes), None

Material: Aluminum, Bronze, Brass

Element Diameters: 0.260″, 0.375″, 0.430″

Max Dia: 1″ to 48″

Max Length: 1.75″ to 40″

Types: Air cooled (finned), Liquid cooled (cooling tubes), None

Terminations: Ceramic insulated screw terminals, Mica insulated screw terminals, Spade tabs, Plain pin, Hermetic seal screw terminal, Terminal lug, Fiberglass sleeving, Armor cable sleeving, SS overbraid, Teflon sleeving, General purpose terminal box, Moisture resistant terminal box, Explosion resistant terminal box, Erge cup

Cooling tubes: Flared Seal brass fitting, Hi-Seal brass fitting, 90° Copper elbow, 90° Brass threaded elbow, Threaded copper fitting

Clamping: Straps, Bolts

Options: Dual cooling tubes, Threaded Nickle plating, Anodizing, Hard-coat anodizing, Teflon, Magnaplate, Non-exposed cooling tubes, Ground studs, Incoloy cooling tubes, Cut outs, Bevels, Stand-Offs